Microchallenge 1

Within the Fab Academy program three microchallenges take place with the first one starting in Feburary. After the general introduction led by Eduardo the challenge started.

Together with Nikita we were interested in given a sequel to the fractal experimentation we did in the first term and decided to dedicate the first microchallenge to elaborate on that principle. The final output of the week can be found on the Emo Sculpting website.

Ideation

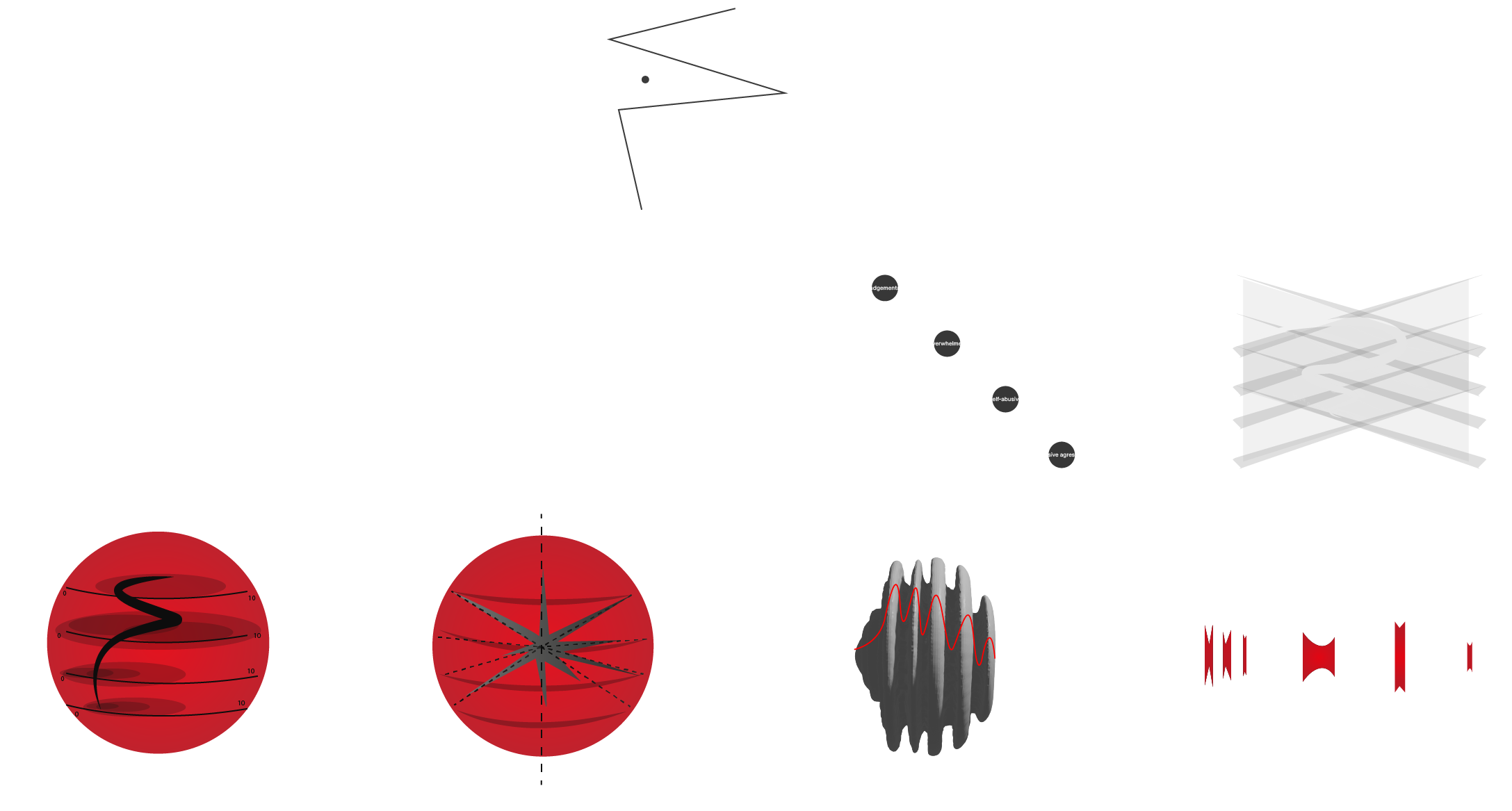

Coding

Based on the iteration outcomes, Nikita focussed on developping the P5.js script while experimenting with coloring, shading, noise and delays. The shape is constructed by bezier curves guided by anchor points that move along four x-axis. These anchor points are defined by four - seemingly - stepless sliders which the user adjusts.

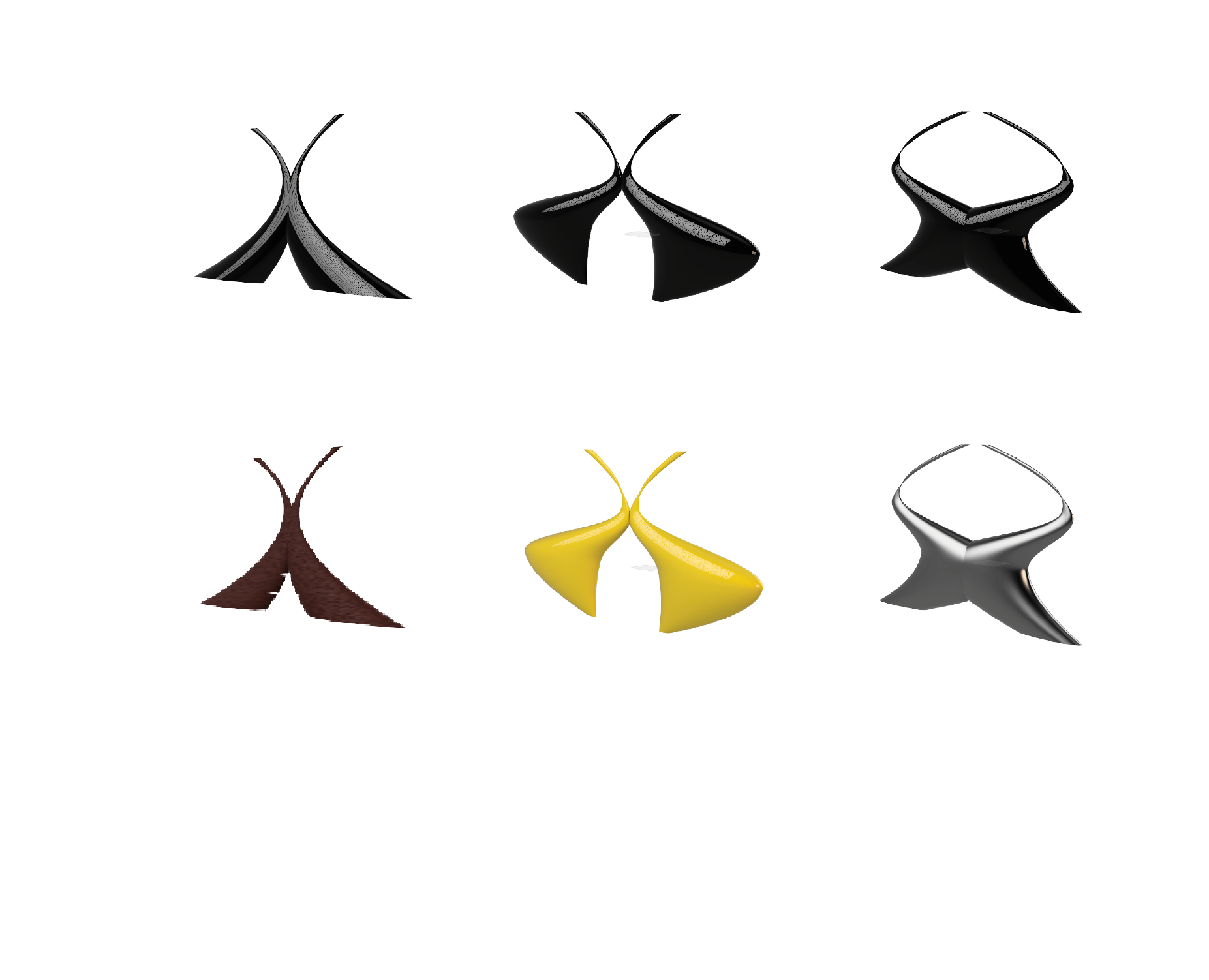

CAD

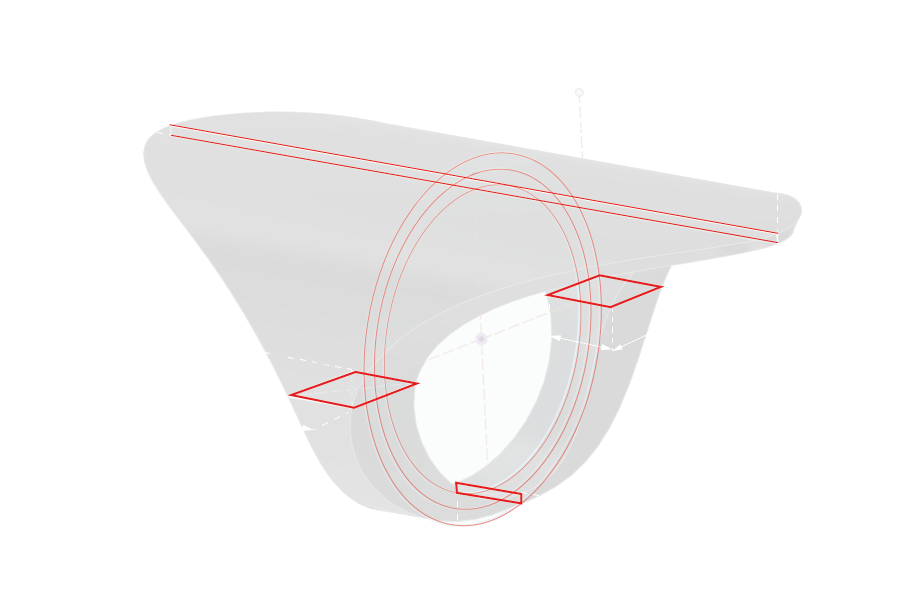

As next step in the physicalization of the defined/indexed emotions I created a parametric design in which the variables are used as input for the shape definition.

As physicalization of our digital tool I used the same parameters in a matrix to generate a 3D shape in Fusion 360. With the file exported as .stl we could use the Fablab's SLA printer and in about 4 hours we had two objectivied emotions in our hands.

SLA printing

The CAD file was exported as .stl from Fusion 360 to the IAAC cloud and opened on the pc controlling the SLA printer. The SLA printer has its own software displaying a preview of both the models and their supports. Edu oriented the models in a way so that the outer/smooth side would not be in touch with the supports aka have the smoothest appearance. The printer ran for four hours. We emptied and cleared the printing bed and placed the two resulting models in an ultrasonic bath for five more minutes to harden the material.

The output were two rings. Their yellow-ish appearance is an side effect of the material hardening.

Learnings

This microchallenge involved a few tools and approaches that were new to me. The most prominent of these was the usage of external variables to generate visualizations and even geometry.

- SLA printing.

- Multi-dimensional parametric design.

- Personalised (jewellery) design.

Repository

We created a repo of the microchallenge that shows more of our process.